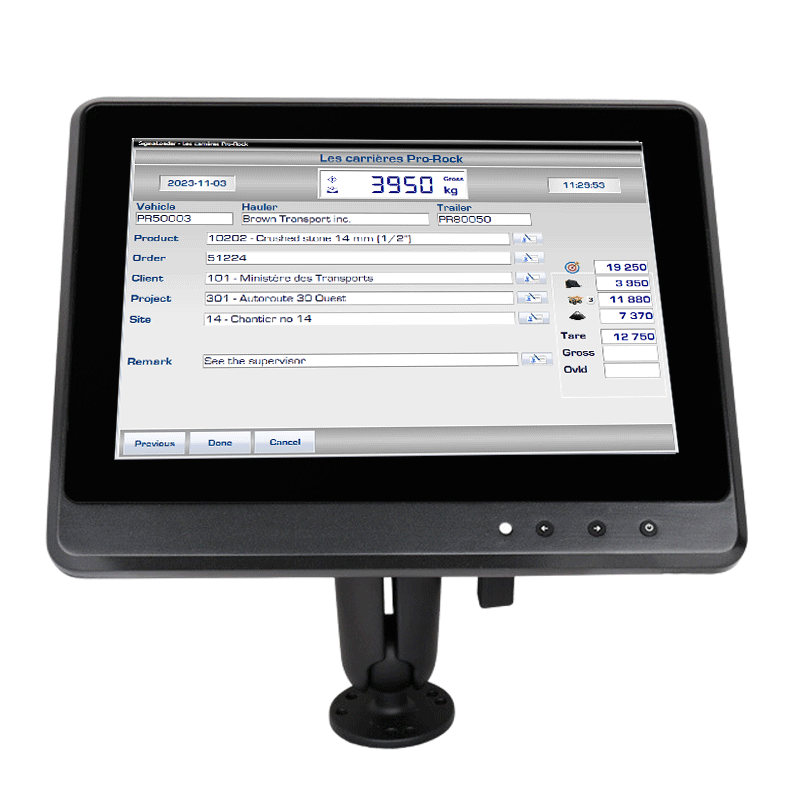

The SigmaLoader terminal is our software solution which allows optimization of loading operations by displaying in real time the list of loadings to be carried out by the loader operator.

This list indicates vehicles, products, quantities to load, waiting times and product locations.

Its user-friendly interface makes it easy for operators to use, ensuring rapid and efficient processing of weighing transactions.

SigmaLoader displays a real-time list of the operations to be performed for loader operators.

This list shows the details of the load, such as vehicle, product, quantity, waiting time and location.

Vehicles are added automatically after weighing the curb weight or RFID identification.

Loader operators can manually enter data, reducing operating costs during periods of low activity. Weighing transactions are made directly by the loader operator.

An integrated scale allows autonomous weighing with printing of weighing tickets. Ideal for sites that are not equipped with a truck scale (weighbridge) or cover operational needs where a truck scale is not required.

The graphical interface is user-friendly and easy to use for operators.

SigmaLoader ensures rapid and efficient processing of weighing transactions, allowing greater flexibility and thus optimizing operations.

In this mode, vehicles to be loaded are automatically added to the list as soon as the curb weight is weighed on the truck scale or when the vehicle is identified as entering the site, whether manually by the weigher or automatically via RFID readers. Thus, the loader operator knows in advance the loading to be carried out and can optimize his movements accordingly.

Download PDFThis mode allows the loader operator to enter transaction information himself. It is particularly useful for reducing operating costs during periods of low traffic or outside of normal operating hours, eliminating the need for a scale weigher. This mode works with a truck scale certified in non-weighing mode.

Download pdfIn this third mode, weighings are carried out with a scale installed on the charger. The module is completely self-contained and weigh tickets are printed directly from the printer in the feeder. All weighing transactions are transferred automatically to the central system. This allows you to maintain total control over your operations.

Download pdfPlease provide the following information to receive the PDF file in your email.

Veuillez fournir les informations suivantes pour recevoir le fichier PDF dans votre courrier électronique.

Please provide the following information to receive the PDF file in your email.

Veuillez fournir les informations suivantes pour recevoir le fichier PDF dans votre courrier électronique.

Veuillez fournir les informations suivantes pour recevoir le fichier PDF dans votre courrier électronique.

Veuillez fournir les informations suivantes pour recevoir le fichier PDF dans votre courrier électronique.

Please provide the following information to receive the PDF file in your email.

Please provide the following information to receive the PDF file in your email.

Please provide the following information to receive the PDF file in your email.

Please provide the following information to receive the PDF file in your email.

Please provide the following information to receive the PDF file in your email.

Veuillez fournir les informations suivantes pour recevoir le fichier PDF dans votre courrier électronique.

Veuillez fournir les informations suivantes pour recevoir le fichier PDF dans votre courrier électronique.

Please provide the following information to receive the PDF file in your email.

Veuillez fournir les informations suivantes pour recevoir le fichier PDF dans votre courrier électronique.

Please provide the following information to receive the PDF file in your email.

Please provide the following information to receive the PDF file in your email.

Veuillez fournir les informations suivantes pour recevoir le fichier PDF dans votre courrier électronique.

Veuillez fournir les informations suivantes pour recevoir le fichier PDF dans votre courrier électronique.